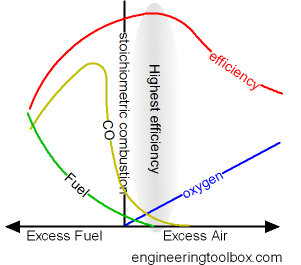

The purpose of excess air in furnace combustion is to ensure complete combustion. This means burning all the fuel. It helps reduce carbon monoxide, minimize soot, and improve how well your furnace works. This guide will explore why air supply is vital for your furnace.

Image Source: www.engineeringtoolbox.com

The Core of Furnace Combustion

The combustion process in a furnace is a chemical reaction. Fuel reacts with oxygen to produce heat. For the furnace to operate efficiently and safely, it requires an optimal air-fuel ratio.

Stoichiometric Air Requirements: The Perfect Mix

Stoichiometry is like a recipe for combustion. It tells us the exact amount of air needed to burn a specific amount of fuel. This perfect amount is the stoichiometric air requirement. If we only had this exact amount of air, the reaction would be perfect. However, reality is more complex.

Why Excess Air is Necessary

In a real-world furnace, getting the perfect stoichiometric mixture is almost impossible. Several factors make excess air necessary:

- Imperfect Mixing: Air and fuel don’t mix perfectly. Some fuel molecules might not find enough oxygen.

- Uneven Distribution: The flow of air and fuel can be uneven across the burner.

- Burner Design: The design of the burner itself affects how well air and fuel mix.

Complete Combustion Benefits: The Goal

Complete combustion is the main goal. It means burning all the fuel completely. Excess air helps achieve this and offers several benefits:

Reducing Carbon Monoxide: A Safety Must

Carbon monoxide (CO) is a deadly, odorless gas. Incomplete combustion produces CO. Excess air helps ensure all carbon atoms in the fuel are fully oxidized to carbon dioxide (CO2), not CO. Reducing carbon monoxide is crucial for safety.

Minimizing Soot Formation: Keeping Things Clean

Soot is unburned carbon. It can coat the inside of the furnace, reducing efficiency. Soot also pollutes the air. Excess air helps ensure complete oxidation of carbon, minimizing soot formation.

Improving Furnace Efficiency: Getting the Most Heat

Improving furnace efficiency means getting more heat from the same amount of fuel. Complete combustion releases the maximum possible heat. By ensuring all fuel burns, excess air helps boost efficiency.

The Role of Excess Air

Let’s delve into how excess air works to achieve the desired outcomes in furnace operation.

Promoting Oxidation: Completing the Burn

The main job of excess air is to ensure every fuel molecule finds enough oxygen to burn completely. This combustion process optimization means that even in areas with poor mixing, there’s still enough oxygen available.

Ensuring Flame Stability: Keeping the Fire Going

A stable flame is essential for consistent heat output. Too little air can cause the flame to flicker or even go out. Excess air helps ensure a more stable and reliable flame.

Managing Temperature: Preventing Overheating

While counterintuitive, excess air can help manage furnace temperatures. Too much heat can damage furnace components. Excess air can absorb some of this heat, preventing overheating and prolonging the furnace’s life.

Finding the Right Balance

Adding too much excess air can also cause problems. Finding the right balance is key to furnace performance enhancement.

Excess Air Drawbacks

- Reduced Thermal Efficiency: Excess air carries heat out of the furnace. This reduces the amount of heat available for warming the space.

- Increased Stack Losses: Heated air escaping through the chimney (stack) represents wasted energy.

- Higher Operating Costs: Wasting heat means you need more fuel to achieve the same level of warmth, increasing operating costs.

Factors Affecting Optimal Air Levels

Several factors influence the optimal air-fuel ratio:

- Fuel Type: Different fuels (natural gas, propane, oil) require different air-fuel ratios.

- Burner Design: The burner efficiency factors, such as how well it mixes air and fuel, affect the optimal air level.

- Furnace Age and Condition: Older or poorly maintained furnaces may require more excess air to compensate for inefficiencies.

- Altitude: Higher altitudes have lower air density, potentially requiring adjustments to the air-fuel mixture.

Air Supply Importance

Air supply importance cannot be overstated. A properly adjusted air supply is essential for safe and efficient furnace operation.

Tools for Measuring and Adjusting Airflow

To achieve the right amount of excess air, technicians use various tools and techniques.

Combustion Analyzers: Measuring the Results

Combustion analyzers measure the levels of various gases in the flue (exhaust) gas. These include:

- Oxygen (O2): Indicates the amount of excess air.

- Carbon Monoxide (CO): Indicates incomplete combustion.

- Carbon Dioxide (CO2): Indicates combustion efficiency.

By analyzing these readings, technicians can adjust the air supply to achieve the optimal balance.

Draft Gauges: Measuring Air Pressure

Draft gauges measure the air pressure within the furnace and flue. Proper draft is essential for drawing exhaust gases out of the furnace and preventing backdrafting.

Adjusting Air Shutters and Dampers

Furnaces have air shutters or dampers that control the amount of air entering the burner. Technicians adjust these to fine-tune the air-fuel mixture.

Keeping Your Furnace in Top Shape

Regular maintenance is crucial for ensuring your furnace operates safely and efficiently.

Regular Inspections: Catching Problems Early

A qualified technician should inspect your furnace annually. They will check the burner, heat exchanger, and flue for any signs of problems.

Burner Cleaning: Maintaining Efficiency

A dirty burner can cause incomplete combustion. Regular cleaning helps maintain optimal efficiency.

Flue Inspection: Ensuring Safe Exhaust

A blocked or damaged flue can cause dangerous backdrafting of exhaust gases. The flue should be inspected regularly and repaired as needed.

The Future of Furnace Combustion

As technology advances, furnace combustion systems are becoming more sophisticated.

Advanced Burner Designs

New burner designs are improving air-fuel mixing, allowing for more efficient combustion with less excess air.

Electronic Controls

Electronic controls can precisely regulate the air-fuel mixture, optimizing combustion in real-time.

Condensing Furnaces

Condensing furnaces extract even more heat from the exhaust gases, further improving efficiency.

In Conclusion

Excess air is essential for safe and efficient furnace operation. It ensures complete combustion, reducing carbon monoxide, minimizing soot formation, and improving furnace efficiency. Finding the right balance is key to furnace performance enhancement. Regular maintenance and professional inspections will help keep your furnace running smoothly for years to come.

Frequently Asked Questions (FAQ)

What happens if my furnace doesn’t have enough air?

Incomplete combustion occurs. This leads to carbon monoxide production, soot formation, and reduced efficiency.

Can I adjust the air supply to my furnace myself?

It’s best to have a qualified technician do it. They have the tools and knowledge to make the adjustments safely and accurately.

How often should I have my furnace inspected?

At least once a year. Regular inspections can catch problems early and prevent costly repairs.

What are the signs of incomplete combustion?

Signs include a yellow or orange flame (instead of blue), soot around the furnace, and a strange odor. If you suspect incomplete combustion, call a qualified technician immediately.

Is excess air the only factor affecting furnace efficiency?

No. Other factors include the age and condition of the furnace, the insulation of your home, and the type of fuel you use.

My name is Carlos Gadd, and I am the creator of AirPurityGuide.com.. With a passion for footwear, I share my experiences, insights, and expertise about shoes. Through my blog, I aim to guide readers in making informed decisions, finding the perfect pair, and enhancing their footwear knowledge. Join me on this journey to explore everything about shoes!