Image Source: aeno.com

A Deep Dive: What Does An Air Purifying Respirator Do

An air purifying respirator (APR) cleans the air you breathe. It takes air from your surroundings and filters out harmful things. This helps protect you from airborne contaminants like dust, fumes, and certain gases. APRs are key respiratory safety equipment. They make sure you breathe clean air in risky places.

Deciphering the Core Function of an APR

An air purifying respirator works simply. It pulls air from around you through a filter. This filter cleans the air. Then, you breathe the clean air. Think of it like a small air cleaner for your face.

This device is vital for breathing air purification. It makes sure bad things in the air do not reach your lungs. This process involves two main ways of cleaning the air. One way is for tiny bits, called particulate matter filtration. The other way is for harmful gases and vapors, known as gas and vapor removal. Both are key parts of its job.

Essential Parts of an Air Purifying Respirator

An APR has a few main parts. Each part helps it work well.

- The Facepiece: This is the part that covers your face. It can be a half-mask, covering your nose and mouth. Or it can be a full-facepiece, covering your eyes, nose, and mouth. The facepiece must seal tightly to your face. This stops dirty air from leaking in.

- Filters or Cartridges: These are where the magic happens. They attach to the facepiece. Air goes through them. These filters catch or stop the harmful things. Different filters block different threats.

- Valves: APRs have valves. Inhalation valves let clean air in when you breathe in. Exhalation valves let your breath out when you breathe out. They stop dirty air from getting in.

Each part works together. They make sure you get clean air to breathe. This system helps keep you safe.

Exploring Respirator Filter Types

Not all air is the same. So, not all filters are the same. Respirator filter types are made for different dangers. Knowing the right filter is vital for your safety.

There are two main types of filters. One type stops tiny bits. The other type stops gases and vapors. Some filters do both jobs.

Filters for Particulate Matter Filtration

These filters stop solid particles and liquid droplets. Think of dust, mist, and fumes. They work like a tiny net. They catch the small bits as air passes through.

In the U.S., these filters have ratings. These ratings tell you how well they work. They use letters (N, R, P) and numbers (95, 99, 100).

- N-Series (Not resistant to oil):

- N95: Blocks 95% of particles.

- N99: Blocks 99% of particles.

- N100: Blocks 99.97% of particles.

- Use these when no oil is present in the air.

- R-Series (Resistant to oil):

- R95: Blocks 95% of particles.

- R99: Blocks 99% of particles.

- R100: Blocks 99.97% of particles.

- Use these if oil mist might be in the air. You can reuse them for a short time.

- P-Series (Oil proof):

- P95: Blocks 95% of particles.

- P99: Blocks 99% of particles.

- P100: Blocks 99.97% of particles.

- Use these if oil mist might be in the air. They can be reused for longer.

The higher the number, the more particles the filter stops. P100 filters are the best for particles. They block nearly all of them.

Cartridges for Gas and Vapor Removal

These cartridges stop harmful gases and vapors. They do not block particles. Instead, they use special stuff inside. This stuff absorbs the gases or makes them harmless. This is crucial for gas and vapor removal.

These cartridges are color-coded. The color tells you what kind of gas they stop.

- Organic Vapor (OV): Black label. Stops things like paint fumes, solvents.

- Acid Gas (AG): White label. Stops things like chlorine, sulfur dioxide.

- Ammonia (AM): Green label. Stops ammonia.

- Formaldehyde (FM): Yellow label. Stops formaldehyde.

- Multi-Gas/Vapor (MG/AG/OV): Brown label. Stops many kinds of gases and vapors.

Some cartridges have more than one color. This means they stop several types of gases. They are vital for hazardous environment protection.

Combination Cartridges

Some filters do both jobs. They can stop both particles and gases. These are often used when there are many dangers in the air. For example, painting involves both fumes (gas) and paint mist (particles). A combination cartridge is needed for this.

Choosing the right filter type is very important. It depends on what dangers are in your air. Always check the labels.

Table: Common Respirator Filter Types and Their Uses

| Filter/Cartridge Type | What It Protects Against | Common Uses | Key Feature |

|---|---|---|---|

| N95/N99/N100 | Non-oil based particles (dust, mist, fumes) | Construction, sanding, grinding, wildfire smoke | Not for oily mists |

| R95/R99/R100 | All particles, resistant to oil (for a single shift) | Painting, spraying, light oil mist areas | Can be used with oil, but limited reuse |

| P95/P99/P100 | All particles, proof against oil (extended reuse) | Welding, heavy oil mist, chemical handling | Best for oil presence, longest reuse |

| Organic Vapor (OV) | Organic gases & vapors (paint, solvents, gasoline fumes) | Painting, chemical mixing, degreasing | Uses activated carbon to absorb gases |

| Acid Gas (AG) | Acid gases (chlorine, sulfur dioxide, hydrogen chloride) | Disinfection, industrial cleaning, chemical spills | Neutralizes acid gases |

| Ammonia (AM) | Ammonia | Agriculture, refrigeration, cleaning | Specific for ammonia gas |

| Formaldehyde (FM) | Formaldehyde | Labs, medical facilities, some manufacturing | Specific for formaldehyde |

| Combination | Particles + specific gases/vapors | Painting, welding, certain chemical processes | Offers broad protection in mixed environments |

Achieving Clean Breathing Air Purification

An air purifying respirator cleans the air you breathe. It does this through a simple but clever process.

First, your lungs need air. So, you take a breath. When you breathe in, the APR pulls air from outside. This air does not go straight into your lungs. Instead, it must first go through the filter or cartridge.

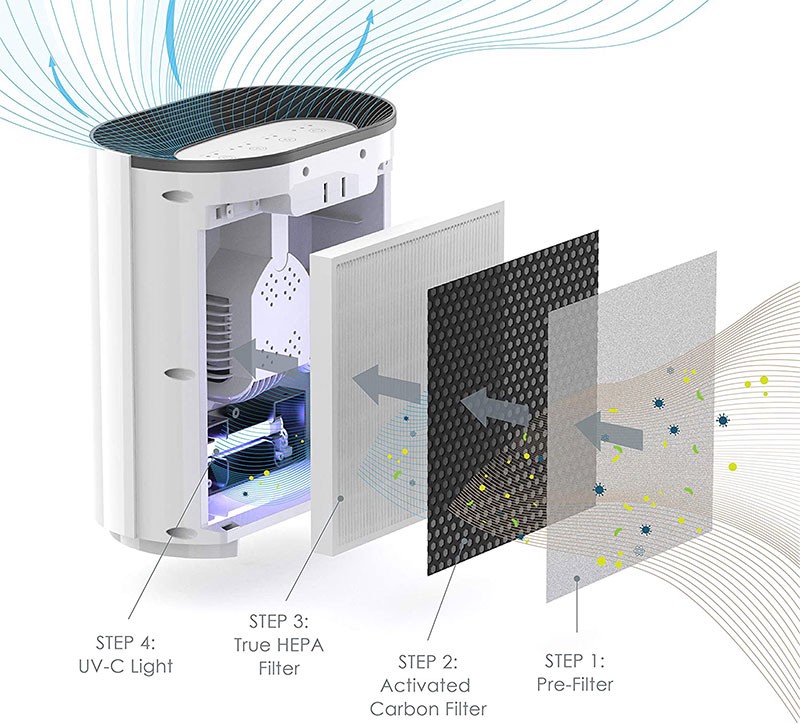

How Particulate Filters Work

Particulate filters are like a maze of tiny fibers. When dirty air goes through, the particles get caught. They stick to the fibers.

- Direct Impaction: Big particles hit the fibers directly and stick.

- Interception: Smaller particles follow the airflow. But they get close enough to a fiber and touch it, then stick.

- Diffusion: Very tiny particles move in a shaky way. They bump into gas molecules. This makes them more likely to hit and stick to a fiber.

The more air that goes through, the more particles the filter catches. Over time, the filter gets full. It becomes harder to breathe through. This is when you know it is time for a new filter.

How Gas and Vapor Cartridges Work

Gas and vapor cartridges work differently. They do not trap particles. Instead, they use special materials to remove gases and vapors. The most common material is activated carbon.

Activated carbon has many tiny pores. These pores are like little sponges. When a gas or vapor molecule enters the cartridge, it gets pulled into these pores. This process is called adsorption. The gas molecules stick to the surface of the carbon.

- Adsorption: The gas or vapor molecules cling to the surface of the activated carbon. They do not soak in, like a sponge absorbs water. They just stick to the outside.

- Chemisorption: For some gases, the chemical reaction makes the gas harmless. The gas molecules change when they touch the special material.

As more gases pass through, the carbon gets full. It can no longer hold new gas molecules. At this point, the cartridge stops working. You might smell the gas you were trying to block. This means the cartridge is “spent” and needs changing. This system provides critical gas and vapor removal.

Both types of filters are key for breathing air purification. They turn dirty air into clean air. This helps keep your lungs safe.

Protection from Airborne Contaminants

Air purifying respirators protect you from many airborne contaminants. These are things in the air that can hurt you if you breathe them in. They can be very small. You might not even see them.

Common airborne contaminants include:

- Dust: From sanding, grinding, cutting, or sweeping.

- Mists: Tiny liquid drops, like from painting or cleaning sprays.

- Fumes: Very fine solid particles. They form when metal is heated and vaporizes, like in welding.

- Gases: Substances that are gaseous at room temperature. For example, carbon monoxide, chlorine.

- Vapors: Gaseous forms of substances that are usually liquid. Like paint thinners or gasoline fumes.

- Biological Agents: Very tiny living things. These include mold spores, some bacteria, and viruses.

An APR filters these things out. This helps with inhalation hazard control. It stops these dangers from getting into your lungs. Breathing in these things can cause big health problems. Short-term issues might include coughing or stinging eyes. Long-term problems can be lung disease or cancer.

APRs are good for many situations. They work well when:

- The air has enough oxygen. APRs do not give you oxygen. They only clean the air that is there.

- You know what is in the air. You need the right filter for the right contaminant.

- The level of the contaminant is not too high. Each respirator has a limit to how much it can filter.

APRs are not for all dangers. They cannot protect you if there is not enough oxygen. They also cannot help if the contaminant is too strong. Or if you do not know what is in the air. In these cases, other types of respirators are needed.

When to Use an APR: Hazardous Environment Protection

Air purifying respirators are often used in jobs where the air is not clean. They provide hazardous environment protection. But they are also useful at home.

In the Workplace:

Many jobs need APRs. Here are some examples:

- Construction: Workers face dust from concrete, wood, and drywall. They might also deal with fumes from glues or paints. An APR with a particle filter is essential.

- Painting and Auto Body Work: These jobs involve paint fumes (organic vapors) and paint mist (particles). A combination filter is usually needed.

- Welding: Welding creates metal fumes and gases. Welders need APRs with specific filters for these fumes. Often, a P100 particle filter is used.

- Chemical Handling: Workers who deal with chemicals might need protection from specific gases or vapors. The right cartridge type is vital.

- Healthcare: Some healthcare workers use N95 respirators. These stop tiny droplets and particles. They protect against viruses and bacteria.

- Agriculture: Farmers might face dust from grains or ammonia fumes from animal waste.

- Mining: Miners face a lot of dust, which can cause lung diseases. P100 filters are often needed.

In these places, employers must check the air. They decide what dangers are there. Then, they choose the right respiratory safety equipment. This helps keep workers safe.

At Home and for Hobbies:

You might also use an APR outside of work.

- Home Improvement: Sanding old paint, insulation, or drywall creates dust. A simple N95 or P95 mask can help.

- Gardening/Landscaping: Some sprays or heavy dust from yard work might warrant an APR.

- Cleaning: Strong cleaning products can give off fumes. A specific gas cartridge might be useful.

- Wildfire Smoke: If you live near wildfires, the smoke contains tiny particles. An N95 or P100 mask can help protect your lungs.

Always match the respirator to the task. Using the wrong one gives no protection. Or it gives too little protection.

Cartridge Service Life: Knowing When to Change

A key part of using an APR is knowing when to change its filters or cartridges. This is called cartridge service life. Filters do not last forever. They get full or stop working. When they do, they stop protecting you.

Factors That Affect Service Life:

Several things make a filter or cartridge last longer or shorter.

- Contaminant Concentration: If there is a lot of bad stuff in the air, the filter gets full faster. If there is less, it lasts longer.

- Breathing Rate: If you work hard, you breathe faster. More air goes through the filter. This means it gets full faster.

- Humidity and Temperature: For gas and vapor cartridges, high humidity and temperature can make them work less well. They might get saturated faster.

- Type of Contaminant: Some gases or particles fill a filter faster than others.

- Filter Type: P100 filters can hold more particles than N95 filters. Some chemical cartridges simply have more sorbent material.

How to Tell If a Filter or Cartridge Is “Spent”:

- Particulate Filters:

- Breathing Difficulty: It becomes much harder to breathe through the filter. This is the most common sign. The filter is clogged with particles.

- Damage: The filter looks torn or dirty.

- Gas and Vapor Cartridges:

- Smell or Taste: You start to smell or taste the contaminant again. This means the cartridge is no longer absorbing the gas. This is a very clear sign.

- Irritation: You feel irritation in your eyes, nose, or throat. This means the gas is getting through.

Important Note: Do not rely on smell or taste alone to tell if a gas cartridge is spent. Some gases are very dangerous even if you cannot smell them. Some you cannot smell at all.

Change Schedules:

The best way to know when to change a cartridge is to follow a “change schedule.” This is a plan that tells you exactly when to change them. It is based on:

- How much of the contaminant is in the air.

- How long workers are exposed.

- Data from the cartridge maker.

Sometimes, a lab test is done. This test shows how long the cartridge will last in specific conditions. Then, the workplace makes a rule. For example, “Change cartridges every 4 hours of use.”

If there is no change schedule, change the cartridge when you smell or taste the contaminant. Or, if you feel irritation. But always check if a change schedule is needed for your specific job. Cartridge service life is key for continuous protection.

Air Purifying vs Supplied Air Respirators: A Key Distinction

Air purifying respirators (APRs) are very useful. But they are not the only type of respiratory safety equipment. Another major type is the supplied air respirator (SAR). Knowing the difference is critical. It helps you choose the right protection.

Air Purifying Respirators (APRs):

- How they work: APRs clean the air around you. They pull air from the room through filters.

- Air Source: The air you breathe comes from your immediate surroundings.

- Limitations:

- Oxygen levels: APRs do not add oxygen. They cannot be used in places with too little oxygen (less than 19.5%).

- High contaminant levels: They have limits on how much they can filter. If the air has too much of a contaminant, an APR is not enough.

- Unknown hazards: If you do not know what is in the air, or how much, an APR is not safe.

- IDLH: They cannot be used in Immediately Dangerous to Life or Health (IDLH) situations. These are places where a short exposure could cause death or serious harm.

- Portability: They are usually light and easy to move around in.

- Examples: Half-mask respirators, full-facepiece respirators, powered air-purifying respirators (PAPRs).

Supplied Air Respirators (SARs):

- How they work: SARs give you clean air from a separate source. This air is usually from a compressed air tank or a large compressor. The air comes through a hose to your facepiece.

- Air Source: The air you breathe is clean, fresh air from a tank or a remote source. It does not come from your immediate surroundings.

- Advantages:

- Oxygen levels: They can be used in places with too little oxygen.

- High contaminant levels: They provide very high protection, even in highly contaminated areas.

- Unknown hazards/IDLH: They are suitable for unknown hazards or IDLH situations.

- Limitations:

- Hose length: The hose limits your movement.

- Air supply: You need a constant supply of clean air.

- Weight: Some SARs, like SCBAs (Self-Contained Breathing Apparatus), are heavy.

- Cost: Often more expensive than APRs.

- Portability: Can be less portable due to hoses or heavy tanks.

- Examples: Airline respirators, Self-Contained Breathing Apparatus (SCBA).

Table: APR vs. SAR Comparison

| Feature | Air Purifying Respirator (APR) | Supplied Air Respirator (SAR) |

|---|---|---|

| Air Source | Filters ambient (surrounding) air | Provides clean air from an external source (tank/hose) |

| Oxygen Dependency | Requires adequate oxygen in the ambient air | Can be used in oxygen-deficient areas |

| Protection Level | Moderate to High (filters specific contaminants) | Very High (provides clean, separate air) |

| Use for IDLH | NO (Not for Immediately Dangerous situations) | YES (Suitable for IDLH environments) |

| Portability | High (self-contained on user) | Lower (tethered by hose or heavy tank) |

| Main Limitation | Does not provide oxygen; filter saturation | Limited movement by hose; air supply duration |

| Typical Contaminants | Particles, specific gases/vapors | Any airborne contaminant, including oxygen hazards |

| Cost (Generally) | Lower initial cost | Higher initial cost and operating expenses |

Choosing between an APR and an SAR depends on the specific dangers. It also depends on the work environment. For inhalation hazard control, the right choice is paramount. An APR is good for known, lower-level hazards with enough oxygen. An SAR is for severe or unknown hazards, or when oxygen is low.

Proper Use and Care of Respiratory Safety Equipment

Having an APR is only half the battle. You must use it correctly and take care of it. This makes sure it works and keeps you safe. These steps are vital for any respiratory safety equipment.

Getting the Right Fit (Fit Testing):

A respirator must seal tightly to your face. If it does not, dirty air can leak in around the edges. This means you are not protected. This is why “fit testing” is so important.

- What it is: A fit test checks if a specific respirator fits your face. It is done by a trained person.

- How it works:

- Qualitative Fit Test: You wear the respirator. Then, a hood is placed over your head. A harmless, strong-smelling or tasting substance (like saccharin or Bitrex) is sprayed inside. If you smell or taste it, the mask does not fit.

- Quantitative Fit Test: A machine measures how much air leaks into the mask. This gives a number (fit factor). A higher number means a better fit.

- Why it matters: Your face shape is unique. One type of respirator might fit you, but not your friend. Fit testing makes sure you have a good seal. You must pass a fit test before using a respirator in a risky place.

User Seal Checks (Every Time You Wear It):

After you put on your respirator, always do a “user seal check.” This is a quick check you do yourself. It makes sure the mask is sealed right now.

- Positive Pressure Check: Close off the exhalation valve. Gently breathe out. The mask should push away from your face slightly.

- Negative Pressure Check: Close off the inhalation valves (or cover the filters). Gently breathe in. The mask should pull tightly to your face. It should stay that way for a few seconds.

If you cannot get a good seal, do not go into the hazardous area. Adjust the mask. Or try a different size or type.

Maintenance, Cleaning, and Storage:

Taking care of your respirator helps it last. It also makes sure it works when you need it.

- Cleaning: After each use, clean your reusable respirator. Use mild soap and warm water. Rinse it well. Let it air dry completely. Do not use harsh cleaners.

- Inspection: Before each use, look at your respirator. Check the facepiece for cracks or tears. Check the straps for damage. Make sure the valves are clean. Look at the filters/cartridges. Make sure they are not damaged. Check that they are not expired.

- Storage: Store your respirator in a clean, dry place. Keep it away from dust, sunlight, extreme temperatures, and chemicals. A sealed bag or container is best. This stops it from getting dirty or damaged.

Proper care extends the cartridge service life. It also ensures the respirator is ready for inhalation hazard control.

Limitations of APRs

Air purifying respirators are very good. But they have limits. It is crucial to know these limits. Using an APR when it is not suitable can be very dangerous. It might not protect you at all.

- Oxygen Deficiency: APRs do not make oxygen. They only clean the air that is there. If the air has too little oxygen (below 19.5%), you cannot use an APR. You would need a supplied air respirator.

- Unknown Contaminants: If you do not know what harmful stuff is in the air, you cannot choose the right filter. Using the wrong filter gives no protection.

- Very High Contaminant Levels: APRs have limits on how much they can filter. If the amount of a harmful substance is too high, the APR might not be enough. It might get overwhelmed quickly. Or the filter might not block enough of it.

- Immediately Dangerous to Life or Health (IDLH) Situations: These are places where a short exposure could cause death, severe harm, or stop you from escaping. APRs are never used in IDLH situations. Only supplied air respirators are allowed here.

- Gas/Vapor Properties: Some gases are odorless. You cannot smell them. So, you would not know if your cartridge was spent. For such gases, a continuous gas monitor or a change schedule is needed. Also, some gases do not absorb well into standard cartridges.

- Facial Hair: Any facial hair (beards, stubble) between the mask and your skin can break the seal. This lets dirty air in. A clean-shaven face is a must for a good seal.

- Medical Conditions: Some health problems, like breathing issues or heart conditions, can make it hard to use a respirator. It makes breathing harder. A doctor should check if you can wear one.

Knowing these limits helps you use APRs safely. It ensures you get the right protection for hazardous environment protection. If an APR is not enough, other respirators are needed.

Selecting the Right APR for Inhalation Hazard Control

Choosing the right air purifying respirator is not a guess. It is a careful process. It starts with knowing the dangers. This process is key for effective inhalation hazard control.

1. Assess the Hazard: What is in the Air?

This is the first and most important step. You need to find out:

- What are the specific contaminants? Is it dust, fumes, gases, vapors, or a mix?

- How much of each contaminant is in the air? This is called the concentration. Special air tests often find this.

- Are there any oxygen problems? Does the air have enough oxygen?

- Is the situation IDLH? Could a short exposure kill you or cause great harm?

This information helps you pick the right respirator type. For example, if it is only dust, a particle filter is needed. If it is an organic vapor, an organic vapor cartridge is needed. If it is both, a combination filter.

2. Check Exposure Limits: How Much is Too Much?

Governments and health groups set “exposure limits.” These limits say how much of a substance people can be exposed to safely. These are like speed limits for chemicals.

Your respirator must lower the contaminant level in your breathing zone below these limits. Each respirator type has an “Assigned Protection Factor” (APF). This number tells you how much it reduces your exposure. For example, an APF of 10 means the respirator can reduce the contaminant by 10 times.

You need a respirator with an APF high enough for the hazard.

3. Consider the Work Environment:

- Workload: Will you be breathing hard? This affects filter life.

- Temperature and Humidity: These can affect cartridge life.

- Space: Is it a small, enclosed space? This might need an SAR.

- Visibility: Full-facepiece respirators can fog up. Or they might make it hard to see if you wear glasses.

4. User Factors:

- Fit: The respirator must fit your face well. This is why fit testing is crucial. No mask protects you if it does not seal.

- Comfort: A comfortable mask is more likely to be worn correctly.

- Other Protective Gear: Does the respirator work with glasses, safety goggles, or helmets?

5. Respirator Program (for Workplaces):

Many workplaces have a written “respiratory protection program.” This program covers:

- Hazard assessment.

- Choosing the right respirator.

- Medical exams for workers.

- Fit testing.

- Training on use and care.

- Maintenance and storage.

- Filter change schedules.

This program makes sure that respiratory safety equipment is used the right way. It ensures worker safety.

By following these steps, you can pick the right air purifying respirator. This is essential for protecting your lungs. It keeps you safe from breathing in harmful things.

Frequently Asked Questions (FAQ)

Can APRs protect against viruses like the flu or COVID-19?

Yes, certain APRs can. An N95 (or higher, like P100) particulate filter can block tiny particles, including those that carry viruses. For these, the “95” means it filters out at least 95% of very small particles. But remember, a tight fit is key. A loose mask does not protect you.

How do I know if my particulate filter (N95, P100) is full?

For particulate filters, the main sign is when it becomes harder to breathe. The filter gets clogged with particles. If breathing feels difficult, or the filter looks dirty or damaged, it is time to change it.

How do I know if my gas/vapor cartridge is full or “spent”?

For most gas/vapor cartridges, you will start to smell or taste the harmful chemical. You might also feel irritation in your nose, throat, or eyes. If you notice any of these signs, leave the area at once and change your cartridge. For some gases, you cannot smell them, so relying on a set change schedule is very important.

Can I reuse respirator filters or cartridges?

It depends on the type.

* Particulate filters (N95, P100): Many can be reused for a limited time if they are not damaged and breathing is still easy. But check the maker’s instructions.

* Gas/vapor cartridges: Once a gas/vapor cartridge is “spent” (you smell/taste the chemical), it cannot be reactivated. You must replace it. Do not try to clean or reuse it. Even if you cannot smell the chemical, once opened, they have a limited shelf life as they can adsorb things from the air, so it’s usually best to replace after a set time or if you’re uncertain.

What is “fit testing” and why is it important?

Fit testing makes sure your respirator fits your face tightly. If it does not seal well, dirty air can leak in. This means you are not protected. Fit testing is done by a trained person. They check if a specific respirator model and size seals to your face. It is crucial for proper protection.

Are all respirators the same?

No, they are not. Respirators come in many types. They protect against different dangers. Some filter air, like APRs. Others supply clean air, like SARs. Always pick the right type for the specific hazard you face. Using the wrong respirator offers no protection.

My name is Carlos Gadd, and I am the creator of AirPurityGuide.com.. With a passion for footwear, I share my experiences, insights, and expertise about shoes. Through my blog, I aim to guide readers in making informed decisions, finding the perfect pair, and enhancing their footwear knowledge. Join me on this journey to explore everything about shoes!